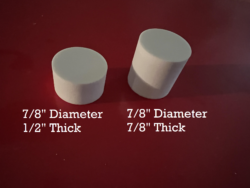

Ceramic Thrust Bearings

How Ceramic Thrust Bearings Work

Unlike conventional roller thrust bearings, Ceramic Thrust Bearings do not rotate. They remain stationery. Due to the nature of the super hard aluminum-oxide ceramic material, they also don’t conduct heat and create very little friction, so they don’t wear out like roller bearings. Eventually, there may be some transfer of metal from the blade and at that time the band saw operator just rotates the bearing a few degrees to allow the blade to run on a new part of the bearing.

Since ceramic guides and thrust bearings do not have moving parts they are not prone to the issues that plague roller bearings: clogging with sap and/or debris, and a tendency to rust in humid or wet conditions.

One of the real benefits of the ceramic thrust bearing is they run quieter and because they are creating less friction the blades last much longer. In fact, our customers say they are getting 40% more life out of their blades.